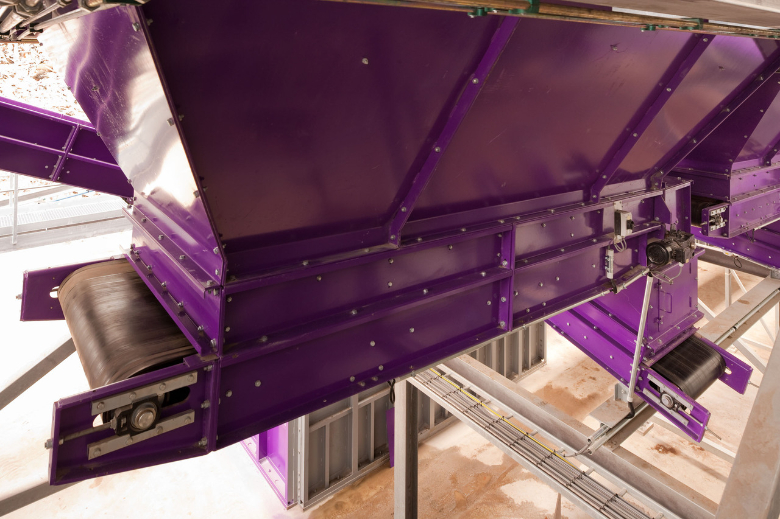

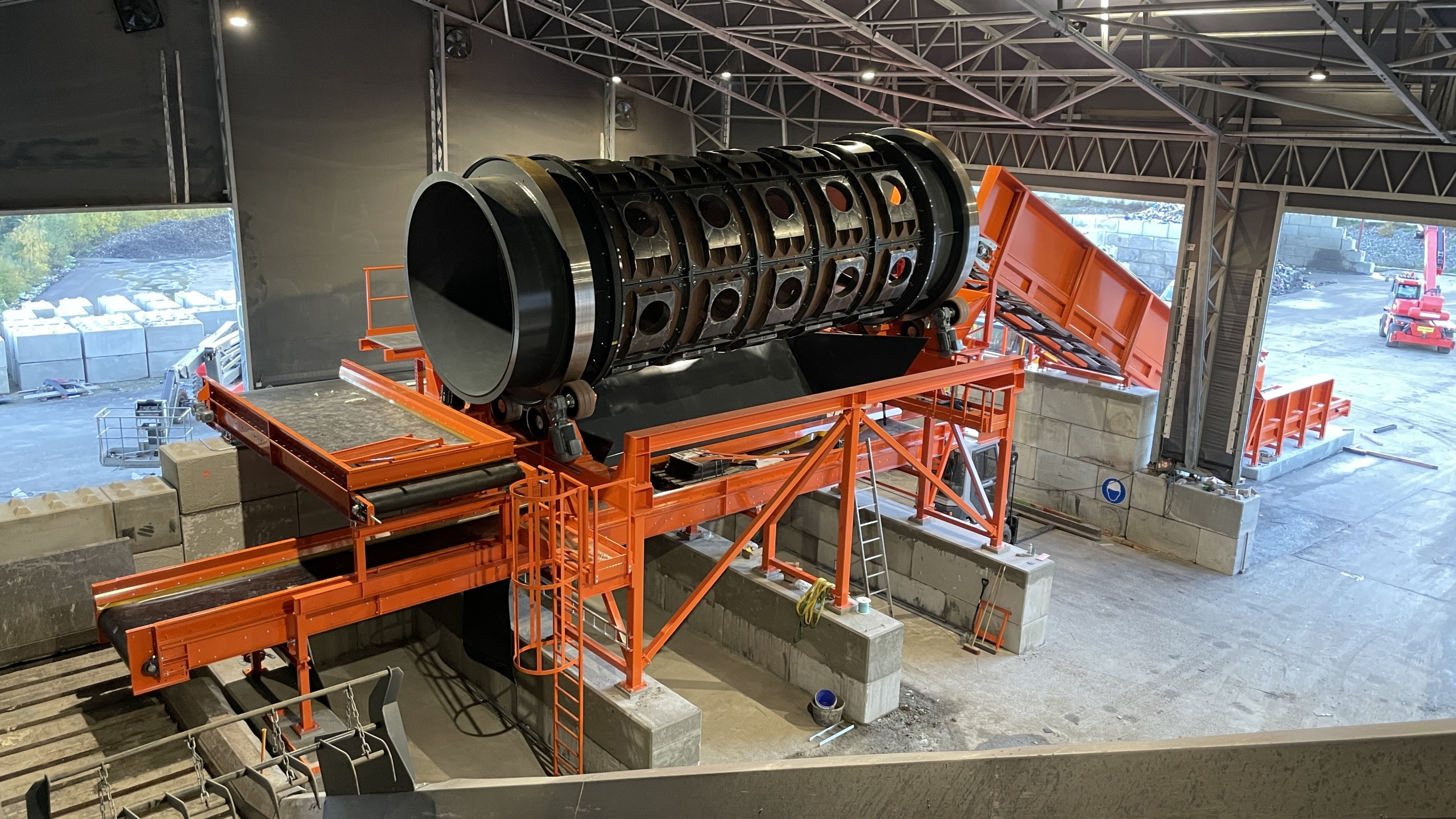

Big-Bag weighing and filling station

In-house, we have developed and manufactured a Big-Bag weighing and filling station. This robust station can fill up to 30 Big-Bags per hour. The unique weighing system ensures that the station has a very high weighing accuracy. In addition, the station is easily operated by one person.

Very flexible station

The great advantage of this Big-Bag weighing and filling station is the simplicity of switching between different materials. This creates a high degree of flexibility. In addition, the bulk density can be adjusted easily, ensuring that the Big-Bag is filled with the correct amount of material. This prevents that too much material is poured into the Big-Bag, which saves on material costs.

How does it work?

The storage bunker, with a maximum capacity of 8 cubic meters, is filled with the desired material (e.g. sand or gravel). By means of a conveyor belt, the material is fed to a funnel. This funnel has a very accurate and reliable weighing system. When the funnel is filled with the correct amount of material, the supply will stop automatically. A forklift truck with a unit for fixing the Big-Bag is placed under the funnel. Next, the shut-off valve opens and the Big-Bag is filled with the correct amount of material. The valve then closes automatically, and the funnel is again filled with the desired amount of material.

Advantages of the Big-Bag weighing and filling station:

- Simplicity of switching between materials and volume ensures a high degree of flexibility

- Highly accurate and reliable weighing unit provides savings on material costs

- Easy operation by a single person

- High capacity of 30 Big-Bags per hour

The possibilities

Busschers’ Big-Bag weighing and filling station can be customized to your specific needs. We can also provide a mobile version. Ask about the possibilities.